I have some slotted angle left over from building utility shelves, so I bolted two pieces together in an inverted T and clamped the rail to my workbench. I had to drill out the mounting bracket on the transformer to take a larger bolt.

I had a large red button sitting around that seemed perfect for this, so I wired it into the circuit and used it to test fixed spark gaps. For the demonstrations in the video below, I removed the button for safety since I would be holding the live lead. The principal rule of high-voltage safety is to avoid becoming a path to ground, so I was wearing shoes with thick rubber soles and leather gloves. The housing of the pushbutton was in contact with the grounded rails, so if I had held the high-voltage electrode in my right hand and pushed the button with my left, I could end up with significant current across my chest. So, one hand in pocket...

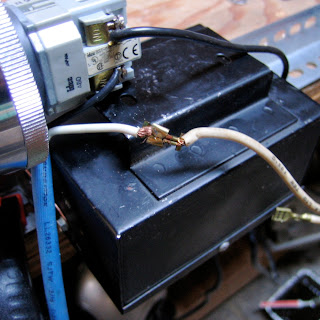

All electrical connections were insulated with heatshrink tubing. The high-voltage output had a ceramic insulated housing, and I did not have the right connector. I did have an old test lead with high-voltage insulation and a banana plug, to which I kept adding insulation until it stopped arcing. I finally had to put a rubber O-ring around it.

And here is a short video of me playing with it.

Oh my that is crazy! Thank for your explanation prior. I would have very worried about your safety had you not explained your process!

ReplyDeleteI figured the "do not try this at home" part was pretty obvious. ;-)

ReplyDelete